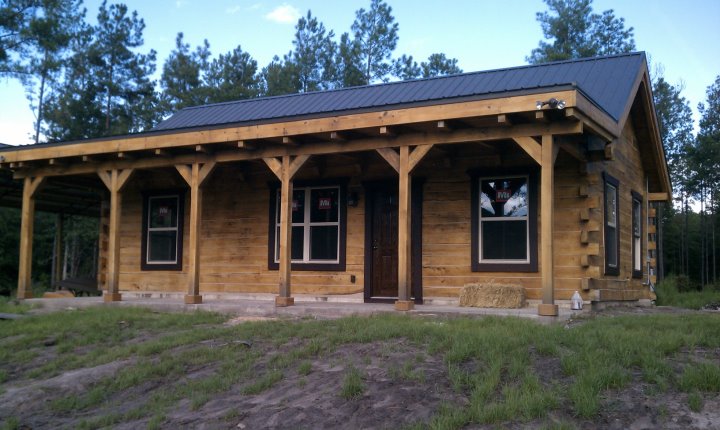

We really don’t need more reasons to live the log cabin lifestyle. For most of us, the beauty, nostalgia, permanence, and peacefulness of living in a log home are all the motivations we need to seek the log cabin life.

Everyone knows log homes are gorgeous, but did you know there are health benefits to living in a log home? The positive effects of wood, how it smells, how it looks, and how it feels helps to encourage relaxation and stress relief. Something else to consider is wood’s natural ability to clean the air which makes log home living a benefit to our lung health.

Folks who struggle with anxiety and depression find they may get relief from their symptoms simply by living in a log cabin in the woods. Living in a log home can increase endorphins, which are hormones that increase your feelings of euphoria and sense of well-being. Muscle tension melts away and blood pressure decreases in the tranquil ambiance of a log home.

Living in a log home can help calm allergies and improve respiratory wellbeing.

Log walls breathe naturally, they allow water vapor to move freely into and out of the wall structure this allows the indoor humidity to remain constant and therefore making it easier to breathe in a log house. Did you know when the relative humidity of indoor air is balanced, molds and bacteria cannot grow?

In addition, the natural Oak in Oak log homes does not off-gas like man-made building materials which are produced with chemicals infused into them. These chemicals release toxins over time into the home. The availability of less nocuous stains and sealers makes log homes a healthier choice.

If you are looking for a home that will encourage a healthy, stress-free life maybe it’s time to look at an Oak log cabin kit from Schutt Log Homes. The log home life is calling you.

LWS

Although Oak is a hardwood and very insect resistant, there is one insect which can be a nuisance to Oak log-home owners. The Powder Post Beetle can be a sneaky little devil. Schutt Log Homes and Millworks has had some experience with these little buggers and we will explain what they are and how to deal with them.

Although Oak is a hardwood and very insect resistant, there is one insect which can be a nuisance to Oak log-home owners. The Powder Post Beetle can be a sneaky little devil. Schutt Log Homes and Millworks has had some experience with these little buggers and we will explain what they are and how to deal with them.

LWS

LWS